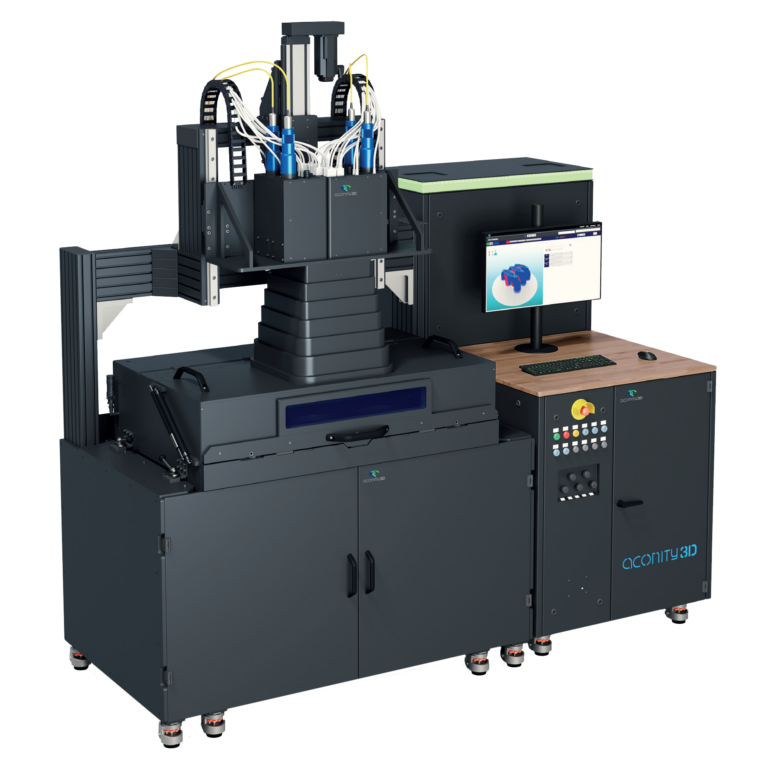

The AconityMICRO is Aconity3D’s very first compact system, designed towards one sole application: MICRO LPBF. At such the systems combines a small spot size of ~ 40 µm and the ability to spread very fine powders in layer thicknesses of < 10 µm due to Aconity3D’s revolutionary vibrating powder deposition.

Further highlights are the completely extractable powder cylinders and built tray which enable end-users to perform a very fast material change and quick start of the process.

The web-based control software AconitySTUDIO suite allows for remote machine access via web sockets as well as complete Job Im- and Export and full control of all relevant process parameters.

The compact machine design, low power consumption, and competable pricing complete the feature list of this specialized LPBF machine.

Technical Specification

F-Theta / 40 μm

3D Scan unit / 50 – 350 μm

Argon 4.6 / 6 bar

Nitrogen / 6 bar

< 5 l/min during process

< 20 l/min during purging