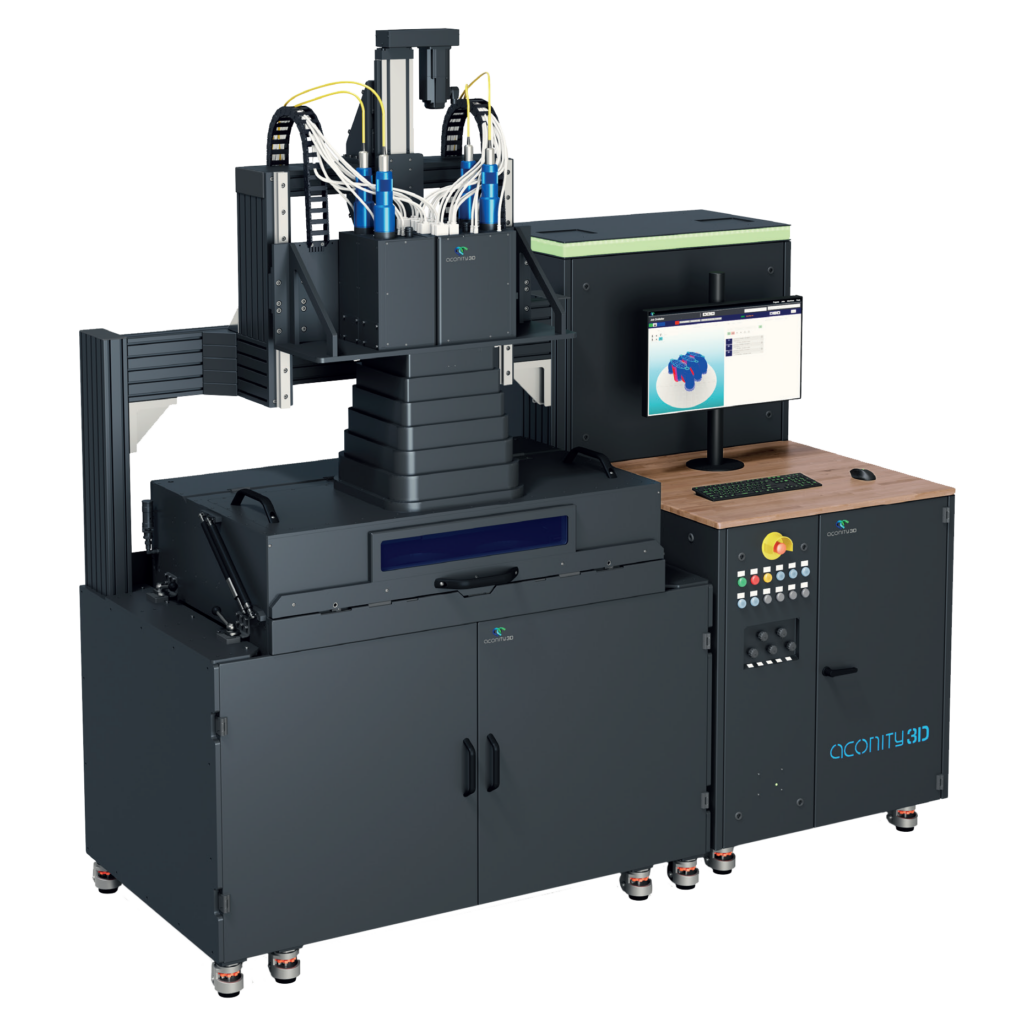

The AconityMIDI+ represents Aconity3D‘s newest machine concept for efficient industrial LPBF application. The exchangeable process chamber allows for parallelized setup times yielding decreased part costs. For maximum material flexibility and quality assurance, high temperature preheating of up to 1000 °C and Aconity3D‘s all-new process monitoring system are available. The AconityMIDI+ is also available with up to 4 Lasers in the QUATTRO-Laser configuration, further increasing productivity.

As for all Aconity systems, the AconityMIDI+ is equipped with the web-based control software AconitySTUDIO, allowing for remote access to all relevant process parameters and machine components.

The AconityMIDI+ is available with a revolutionary Multi-Material powder deposition system, allowing for the manufacturing of Dual-Metal parts.

The passivation of the filter ensures fluent 3D printing and decreases operational expenses. Recycling of the powder can be optionally performed by AconitySIEVE – an automatic sieving station utilizing inert gas to prevent material degradation.

Technical Specification

Ø 170 mm x H 250 mm (optional reduction)

Ø 100 mm x H 250 mm (optional reduction)

Ø 55 mm x H 250 mm (optional reduction)

F-Theta / 80 μm

3D Scan unit / 80 – 500 μm

Coaxial high speed CMOS

Camera for inline process view

Thermo camera for lateral process monitoring in IR spectrum

1000 °C / Ø 150 mm x H 150 mm

Argon 4.6 / 6 bar

Nitrogen / 6 bar

< 5 l/ min during process

< 30 l/ min during purging

Worth noticing – FIRST EVER DUAL-METAL PART PRINTED VIA LPBF – The first multi-material copper/steel part is printed by means of LPBF on an AconityMIDI+. For that purpose, the system is equipped with the optional all new powder deposition system from Aerosint. The processed material combination was stainless steel (1.4404) and a copper alloy (CuCrZr).