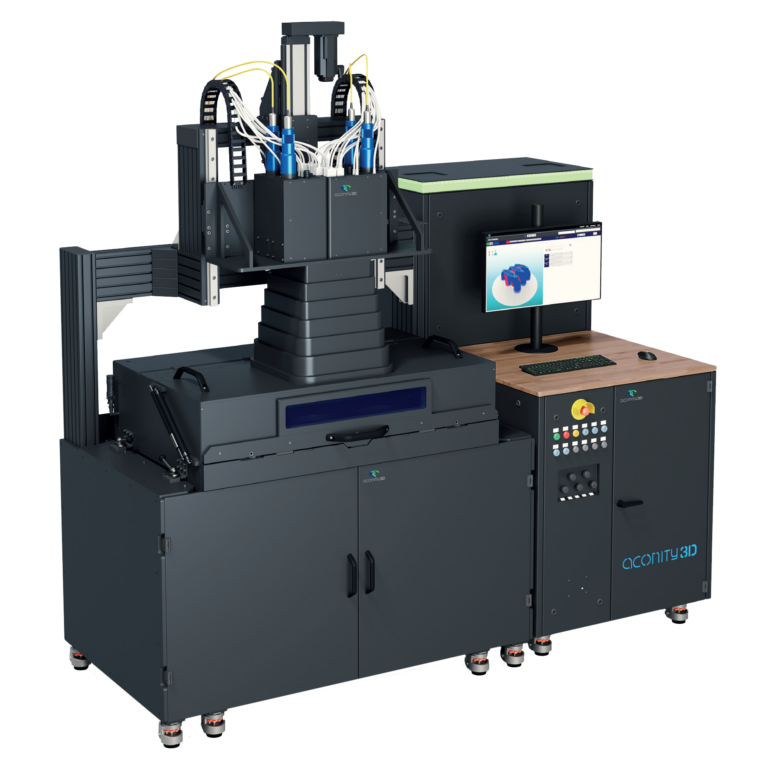

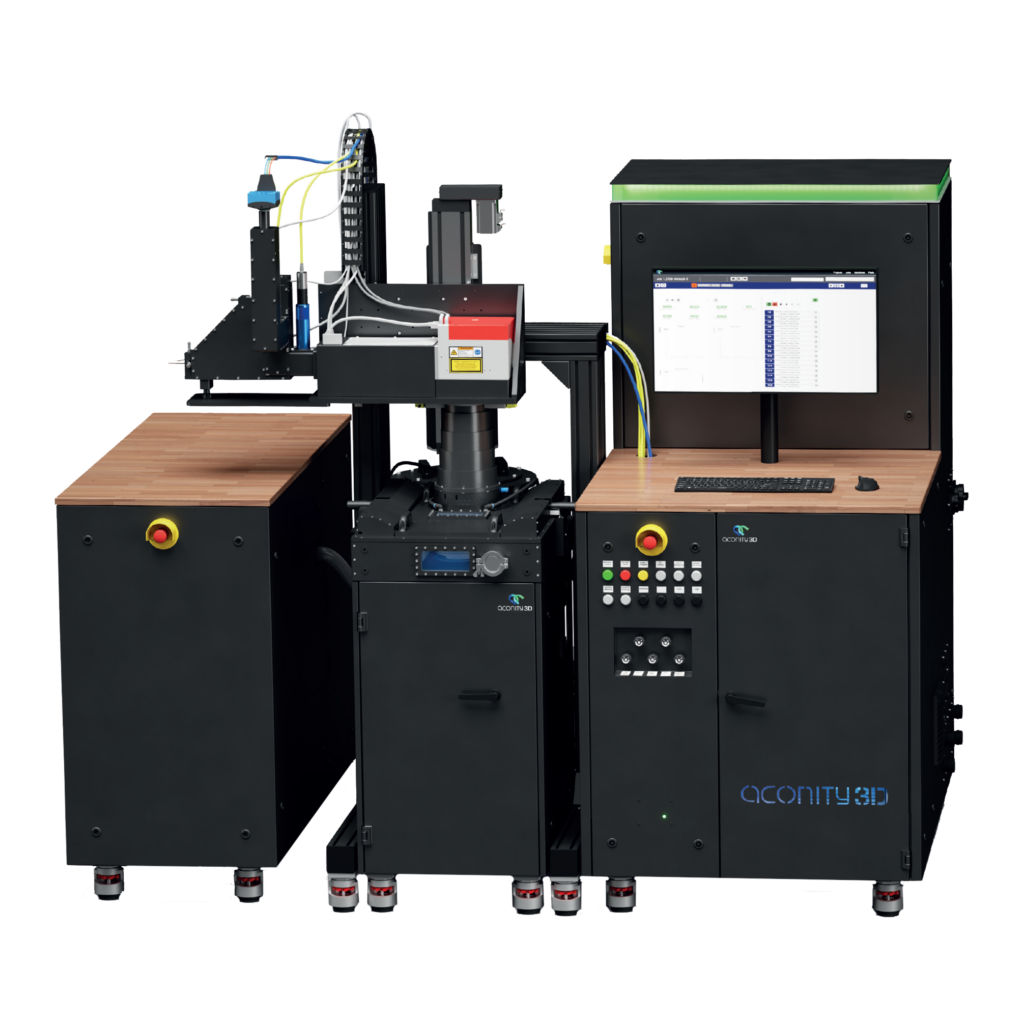

The AconityMINI represents Acontiy3D’s entry-level AM system. A build space of Ø 140 mm, which can be optionally downsized up to Ø 25 mm, allows efficient material research. Also, AconityMINI is a great choice for fast small part and small batches production. Equipped with a strong recirculation, this system allows for the processing also highly reactive materials which exhibit large amounts of weld fumes.

As for all Aconity systems, the AconityMINI may be equipped with further options such as 800°C preheating, and process monitoring, but also a unique vacuum option and a micro-LPBF add-on.

The AconitySTUDIO control software allows for full control of all relevant process parameters as well as remote access through the web interface.

The passivation of the filter ensures fluent 3D printing and decreases operational expenses. Recycling of the powder can be optionally performed by AconitySIEVE – an automatic sieving station utilizing inert gas to prevent material degradation.

Technical Specification

Ø 25 mm x H 190 mm (optional reduction)

Ø 55 mm x H 190 mm (optional reduction)

Ø 100 mm x H 190 mm (optional reduction)

QCW Single Mode Green 200 W / 500 W

F-Theta / 80 μm

3D Scan unit / 80 – 500 μm

3D Scan unit Green 535 nm / approx. 50 – 250 μm

Coaxial high speed CMOS

Camera for inline process view

Thermo camera for lateral process monitoring in IR spectrum

800 °C / Ø 100 mm x H 130 mm

Argon 4.6 / 6 bar

Nitrogen / 6 bar

Vacuum / < 2 mbar

< 5 l/min during process

< 30 l/min during purging

0 – 5 l/min for vacuum

Worth noticing – ACONITY GREEN – Aconity3D has built the first component from pure copper (CU-ETP). The work was performed on an AconityMINI with a laser in the green wavelength range.

The integration of a laser beam source in the green wavelength range is offered as an option for the AcontiyMINI.