Home » Machines

Machines

Laser Powder Bed Fusion (LPBF) technology is one of the most widespread metal additive manufacturing (AM) technologies. A metal part is formed layer-upon-layer, as the laser power selectively melts the metal powder layer by layer. LPBF AM technology solves some of the difficulties/limitations in traditional manufacturing processes and is particularly suitable for metal parts with complex geometry, internal micro-tunnels, and special structure designs.

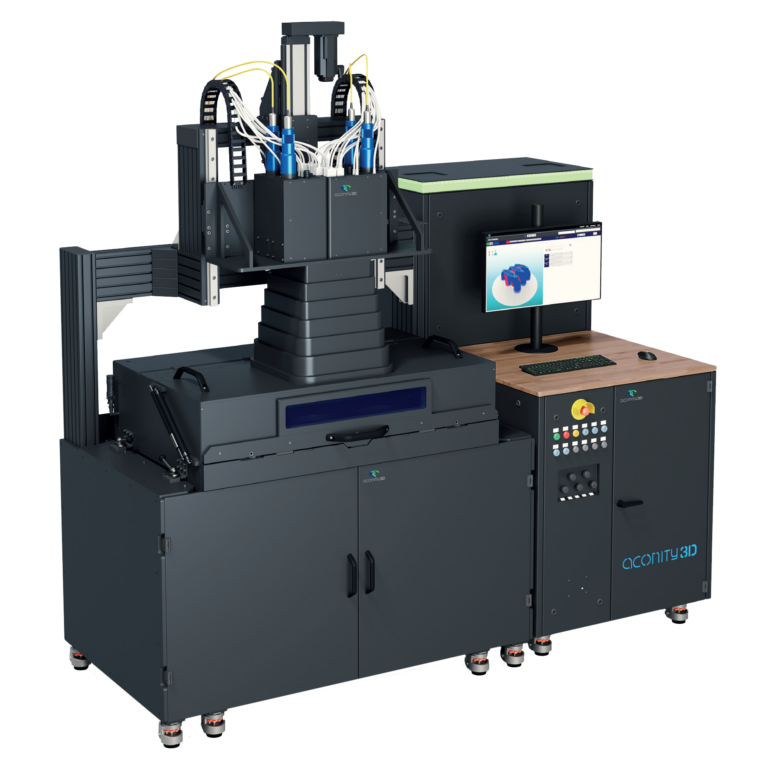

ET Additive is an official distributor of LPBF metal AM machines made by Aconity3D in the markets of the Czech Republic and Slovakia. Aconity3D offers several standard 3D printing machines, which cover a wide range of needs. On top, the machines can be modified easily by Aconity’s modular platform and therefore enable tailor-made additive manufacturing solutions.

Aconity3D benefits:

- Flexible machines suitable for wide range of industrial and R&D applications

- Remote machine control via AconitySTUDIO and web-based interface

- Full-Overlap Multi-Laser configuration (YT video)

- Opened process parameters for user’s modification

- Optional build space reduction for 3D printing of small parts or batches

- Master / Slave operation for selective Laser-preheating (YT video)

- Changeable processing chambers for parallel 3D printing

- Focused laser beam size diameter 40 – 500 μm

- Multi-Material option (YT video)

- High- temperature preheating up to 1200 °C

- Advanced inline process monitoring (YT video)

- Pure copper 3D printing via green laser (YT video)

- MICRO LPBF 3D printing of tiny parts demanding high resolution

- 3D printing in vacuum

- Easy and fast exchange of the materials

- Printable materials: AlSi10Mg, 1.4404/ SAE 316L, Ti6AI-4V, CuCr1Zr, In718, 1.2709/M300, CoCrMo, Magnesium AZ91D, Scalmalloy®, Pure Cu, Titanium Grade 2, Nitinol