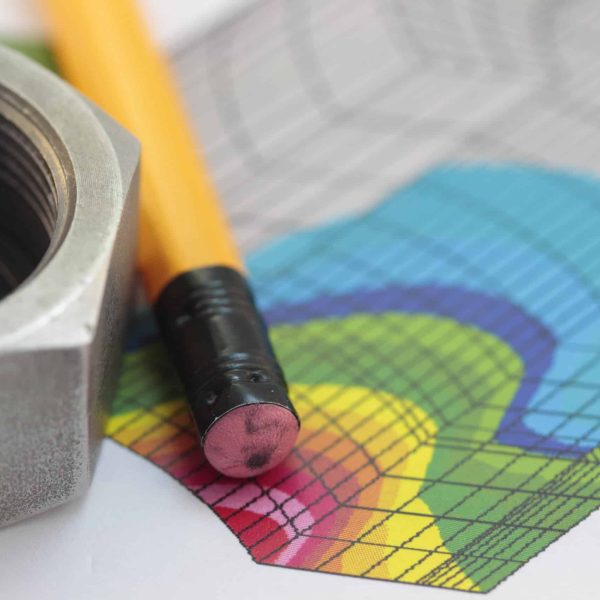

Speaking of metal AM, the design phase is crucial for the successful use of the technology. The designer has to be aware of the constraints and also he/she has to be capable of using the full potential of the technology – the unique potential of metal AM occurs mostly in the design freedom. Without that, your metal AM applications will barely be competitive compared to other technologies. Besides CAD design, it is often desirable to use methods of CAE too in order to reach the optimal design for a given application. We speak about topology and geometry optimizations, generative designs, stress-strain analysis, multiphysics calculations, and so on. For those lacking the CAD designers or CAE engineers experienced with metal AM, we offer either outsourcing our design services on demand or consulting the customer’s design challenges via our customer support.

For the cases when only the physical part (without CAD data representing it) is available, the processes of 3D scanning and reverse engineering can be used in order to obtain such CAD data that are always necessary for metal AM production. We are ready to provide you with these services as well.

Icon box 1 - Title

Icon box 1 - Short Text will be here...

Icon box 2 - Title

Icon box 2 - Short Text will be here...

Icon box 3 - Title

Icon box 3 - Short Text will be here...